Walk into any modern machine shop and you’ll likely hear the steady hum of equipment shaping raw materials into precise components. One of the main drivers of this transformation is a CNC turning service, which has become a cornerstone of how industries produce parts today. From aerospace to automotive, CNC turning makes it possible to achieve accuracy and efficiency on a scale that was almost unimaginable just a few decades ago.

What CNC Turning Really Means

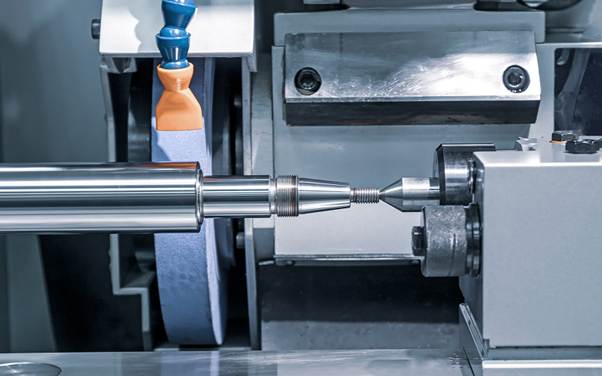

CNC turning is essentially the process of spinning a workpiece on a lathe while a cutting tool removes material to create the desired shape. What sets it apart from manual turning is the use of computer numerical control—meaning every move is pre-programmed, so the result is predictable and exact. Whether it’s a simple shaft or a complex fitting, the process ensures that every part produced matches the design specifications down to the smallest detail.

The Inner Workings of the Machines

Once programmed, a CNC turning machine can run the same job thousands of times with almost no variation. The software dictates everything from spindle speed to tool positioning, which eliminates the guesswork and fatigue associated with manual operations. What’s even more impressive is that these machines can work with a wide range of materials, including plastics, alloys, and hardened steels. Switching between jobs has also become much easier, allowing shops to stay flexible and keep up with customer demands.

Why Tooling Makes a Difference

The success of CNC turning doesn’t just come from the machines themselves. The cutting tools matter just as much. Thanks to innovations in coatings and tool design, modern tooling can withstand high speeds and longer production runs without dulling. This keeps production lines running smoothly and minimizes downtime. And when parts require specific internal features, processes like broaching are often used alongside turning. This technique uses a specially designed tool to cut shapes like splines or keyways, adding details that turning alone can’t achieve.

The Benefits for Manufacturers

For companies, the biggest advantage of CNC turning is consistency. Every part is produced to the same standard, which is vital when thousands of identical pieces are needed. It’s also fast—once the setup is done, machines can keep running with little intervention. That efficiency translates into cost savings, which is why businesses of all sizes rely on CNC technology to stay competitive.

How Technology Keeps Evolving

CNC turning has come a long way in just a short time. Many machines now include live tooling, which allows secondary operations like drilling or milling to be done without moving the part to another setup. This means fewer steps, faster turnaround, and less chance for error. Add in smart monitoring systems, which track tool wear and machine performance in real time, and it’s clear how far the technology has advanced. Shops can spot problems before they slow down production, keeping everything on schedule.

Where Broaching Fits In

While CNC turning covers most needs, some designs require a little extra help. That’s where broaching comes in. By pulling or pushing a toothed tool across the material, broaching creates shapes and features that other methods would take much longer to produce. When paired with CNC technology, it becomes a powerful tool that expands what manufacturers can achieve, especially when time and precision are critical.

Looking Toward the Future

The next phase of CNC turning is all about smarter systems and more automation. Machines are increasingly connected to digital platforms, giving operators real-time insights and even allowing remote monitoring. Artificial intelligence is also starting to play a role by predicting maintenance needs before breakdowns happen. For any business relying on a CNC turning service, these changes point to faster, more reliable, and more cost-effective production.

Conclusion

CNC turning has completely reshaped manufacturing, making it possible to produce parts with unmatched speed and precision. Combined with complementary techniques like broaching and supported by ongoing advancements in automation, it remains one of the most valuable processes in modern industry. If you’re exploring ways to improve your production and keep up with today’s demands, reach out to Disk Precision Group today and discover how CNC turning can make a difference for your business.