Plating Solutions Uncovered: Why Nickel Plating Matters

November 3, 2025 Off By Paul watsonFrom smartphones to aircraft engines, surface finishes play a bigger role in our lives than most people realise. They’re the quiet protectors of technology by preventing rust, adding strength, and even boosting performance. Among the many plating solutions available, nickel plating stands out as one of the most versatile and reliable. Often hidden behind shiny surfaces, nickel plating is what ensures durability, conductivity, and corrosion resistance. Let us explain why nickel remains a cornerstone of plating solutions in industries around the world.

What Really Happens During Nickel Plating

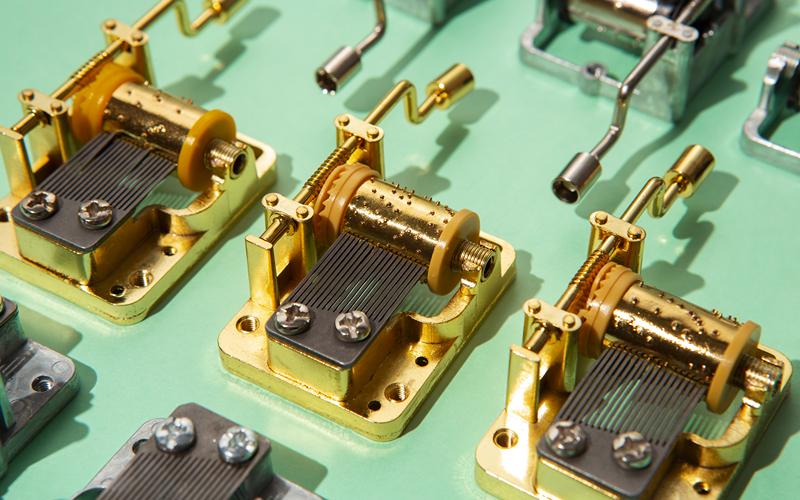

Nickel plating is more than dipping a metal into a shiny bath. Behind the scenes, it’s a highly controlled electrochemical process. Components are first cleaned thoroughly, often through mechanical polishing and chemical treatment, to ensure no dirt or grease interferes with adhesion.

Next, they are submerged in an electrolyte bath containing nickel salts. With the help of an electric current, nickel ions migrate and form a thin, uniform layer on the surface of the item.

The process can be adjusted depending on the purpose. Decorative nickel plating produces a bright, smooth finish often used in consumer goods. Functional nickel plating, on the other hand, provides hardness and wear resistance for machinery or electronic parts.

A good plating solution must balance efficiency, quality, and consistency, which is why skilled technicians carefully monitor current density, bath chemistry, and temperature throughout the procedure. What many don’t see is how precise the science needs to be: too little nickel and the layer won’t last; too much and it can become brittle. This glimpse shows that nickel plating is equal parts art and chemistry.

Where Plating Solutions Are Heading

Plating solutions, like every technology, continue to evolve. One major trend is the growing demand for environmentally friendly methods. Traditional nickel baths can generate waste that requires careful disposal, so research is ongoing into sustainable electrolytes and recycling techniques. Companies are working to reduce their environmental footprint while maintaining the reliability of nickel finishes.

Another trend is miniaturisation. As electronics shrink, so too must the precision of nickel plating. The demand for micro-connectors, sensors, and fine components pushes the industry to achieve thinner, more consistent layers without sacrificing durability.

Finally, industries such as renewable energy and electric vehicles are driving innovation. Nickel plating is being applied to connectors, batteries, and components that must operate reliably under extreme conditions. The future of plating solutions will likely combine sustainability, precision, and new applications, ensuring nickel plating continues to be a mainstay in manufacturing.

How to Understand Nickel Plating Step by Step

For anyone unfamiliar with the process, think of nickel plating as layering armour on a metal surface. Step one is preparation. Without a clean base, the armour won’t stick. This involves polishing and chemical cleaning.

Step two is immersion in the nickel bath. Here, electricity plays the role of messenger, carrying nickel ions and depositing them evenly across the item.

Step three is control: monitoring the conditions so the layer is uniform and strong. Finally, the plated item is rinsed, dried, and sometimes polished to achieve the desired finish.

For industries using nickel plating, the steps may appear straightforward but require strict attention to detail. Errors at any stage can compromise the finish. That’s why professional plating solutions are crucial to ensure every step is performed consistently and meets international standards.

What to Avoid in Nickel Plating

Like any technical process, nickel plating has pitfalls. One common mistake is inadequate cleaning before plating. Even microscopic grease or dust can prevent the nickel layer from bonding properly, leading to peeling or blistering later. Another error is uneven current distribution, which can result in patchy thickness or rough textures.

Over-plating is also a risk. While a thicker layer might seem better, it can make the surface brittle, reducing flexibility and potentially causing cracks under stress. On the flip side, underplating provides too little protection, leaving parts vulnerable to corrosion.

Finally, ignoring maintenance of the plating bath can degrade quality. If the solution’s chemistry is unbalanced, impurities can cause dull finishes or structural weaknesses. Professional oversight helps avoid these mistakes, ensuring that nickel plating delivers the durability and performance industries rely on.

Conclusion

Nickel plating is a precise, adaptable process that strengthens materials, prevents wear, and enables industries to operate reliably. It requires expert control to be more sustainable and precise, and it combines science and technique to ensure long-lasting quality. For businesses seeking reliable plating solutions, nickel remains a proven choice. Its blend of functionality and affordability ensures it will continue to underpin products we use every day, from smartphones to satellites. In a world that depends on durability, nickel plating keeps industries shining.

Curious about how nickel plating could enhance your components? Explore professional plating solutions at Epson Plating today and see how precision, strength, and sustainability can work together.