Mounting styles directly influence hydraulic cylinder performance by determining how loads transfer between cylinders and equipment structures. The connection method affects side load resistance, angular stress distribution, structural alignment maintenance, and overall system longevity. Extending and retracting forces are handled differently by fixed, pivotal, and trunnion mounts. Proper mounting selection prevents premature seal wear, rod bending, and barrel distortion. These problems occur when mounting styles mismatch application demands. Engineers must evaluate force vectors, movement patterns, and structural constraints before specifying mounting hardware.

Load distribution effects

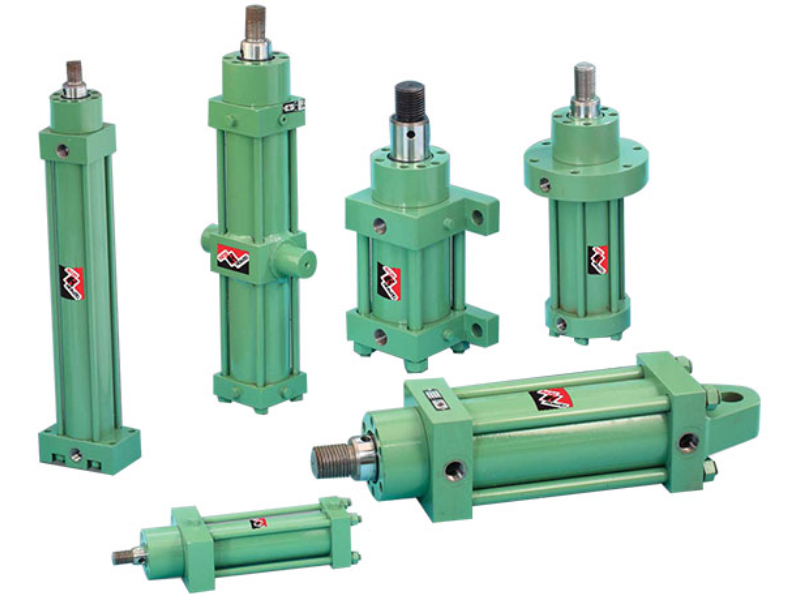

Mounting configurations determine how cylinder forces distribute across attachment points and supporting structures. Fixed mounts, like flange connections, anchor cylinders rigidly at one end. All angular misalignment creates bending stress on the rod. The stress concentrates at the seal gland where the rod enters the barrel. Pivot mounts allow rotation at attachment points. This accommodates equipment movement during operation without generating internal stress. Cylinder selection processes on pressure ratings and fluid flow parameters are detailed under https://northernhydraulics.net/hydraulics-shop/hydraulic-cylinders, ensuring stable operation across demanding industrial setups.

Clevis mounts permit rotation in single planes through pin joints. Rod eyes and clevis brackets create mechanical pivots that absorb angular deflection up to certain limits. Trunnion mounts fix cylinders at mid-barrel positions rather than at ends. The cylinder body pivots as the rod extends and retracts. Each mounting type directs forces along different paths through the cylinder structure. This knowledge helps predict failures under service conditions.

Side load resistance

Different mounting styles vary dramatically in their ability to handle side loads perpendicular to the rod axis. Fixed mounts offer no side load accommodation whatsoever. Any misalignment forces the rod to bend or the barrel to distort under pressure. These deformations damage seals and score chrome plating. Clevis mounts handle side loads in the plane of rotation. They resist forces perpendicular to the pin axis. Double-acting cylinders with opposing clevis mounts must maintain precise alignment. Side forces develop rapidly when linkages move out of the plane. Spherical bearings in mounting hardware accommodate multi-axis angular deflection:

- Self-aligning spherical bearings allow several degrees of rotation in all directions

- Side loads get distributed across bearing surfaces rather than concentrating at seal interfaces

- Misalignments during installation or equipment settling over time get absorbed automatically

- Wear occurs in replaceable bearing components rather than expensive cylinder internals

Trunnion mounts naturally handle side loads better than end mounts. The pivot point sits near the cylinder’s center of mass. This balanced configuration reduces moment forces that would otherwise bend rods or barrels.

Angular movement accommodation

Equipment linkages rarely move in perfectly straight lines throughout their range of motion. Arms pivot around fixed points. Frames flex under load. Structures settle over time. Mounting styles must accommodate these angular changes throughout operating cycles without generating destructive forces. Fixed-mount cylinders demand perfect alignment that rarely exists in real applications. Rod buckling occurs when compressed cylinders encounter even minor angular deviation from straight-line motion.

Pivot-style mounts absorb angular changes through rotation at pin joints. The clevis pin becomes a wear point requiring periodic inspection and replacement during regular maintenance. Proper lubrication at pivot points reduces friction that otherwise resists angular movement. Friction creates stress concentrations at the pins themselves. Grease fittings allow field lubrication without disassembly. Some applications use permanently lubricated bushings that eliminate maintenance requirements.

Application-specific mounting

Different industries favor specific mounting styles based on typical equipment geometry and loading patterns encountered in daily operation. Mobile equipment frequently uses clevis mounts. Their angular accommodation suits excavator arms and loader linkages that move through complex paths. Industrial presses employ flange mounts. Rigid positioning maintains precise alignment between cylinder, ram, and die surfaces. Marine applications prefer trunnion mounts. Their stability during vessel motion prevents binding when ship hulls flex in rough seas. Proper mounting selection based on actual operating conditions extends service life and prevents premature failures from mismatched mounting hardware configurations.